Lifecycle Cost of Bathroom Fixtures: Why the Initial Faucet Price Isn’t the Whole Story

Bathroom fixture specification in architectural and engineering projects calls for a lifecycle-based approach, particularly in commercial and institutional buildings. A first-cost approach will bypass very important aspects like durability, water usage, maintainability, accessibility, and long-term compliance. This article looks at faucet and fixture selection from a lifecycle cost perspective. The technical approach, without salesmanship, is for the AEC professional.

Regulatory and performance frameworks influencing life cycle cost

CALGreen

Green Building Standards Code in California sets the maximum allowable flow rates and fixture efficiency requirements.

WaterSense

WaterSense provides performance-based criteria for water-efficient faucets and describes commercial usage recommendations.

EPA commercial faucets guidance

EPA guidance for commercial faucets.

EPA residential faucet technical sheet

EPA technical sheet for bathroom sink faucets.

ASME A112.18.1 / CSA B125.1

These standards define the performance and safety criteria for plumbing supply fittings related to material certification, pressure performance, and mechanical reliability.

ADA and ICC A117.1

ADA accessibility requirements specify operable parts shall not require tight grasping, pinching or twisting of the wrist, and shall not require more than 5 lbf of operating force.

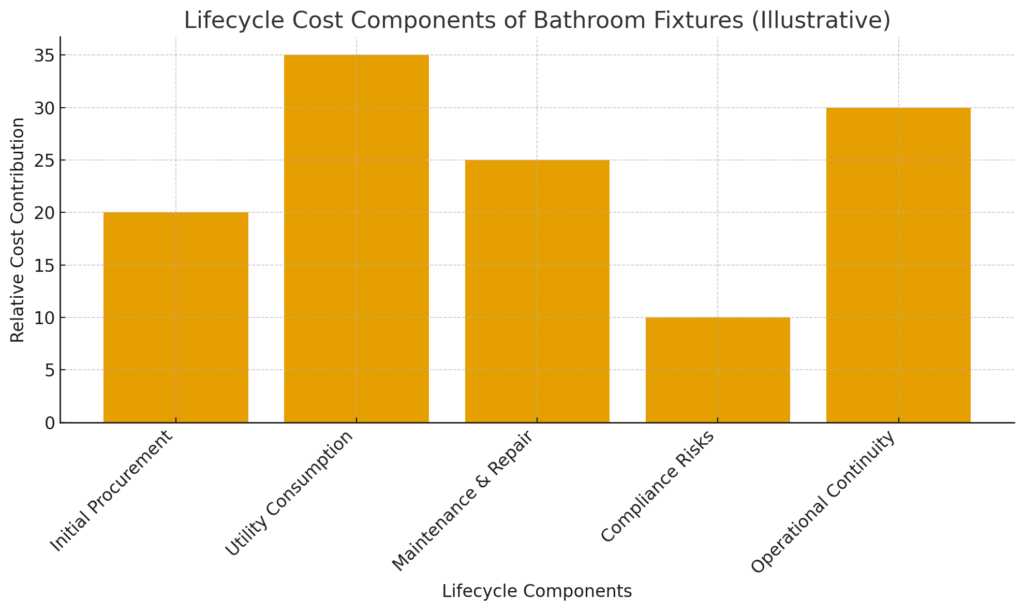

Understanding Lifecycle Cost

Lifecycle cost includes all the costs related to owning a faucet over its service life:

- Initial procurement: fixture cost, valves, and installation labor

- Utility consumption: water use, heated water demand, wastewater load

- Maintenance and repair: cartridges, O-rings, solenoids, sensor components, finish degradation

- Compliance risks: retrofits triggered by updated codes or accessibility audits

- Operational continuity: downtime, spare parts, and standardization across building portfolios

A low initial price rarely reflects true cost of ownership in medium- or high-traffic restrooms.

Durability and Mechanical Performance

Alloy and Internal Components

The commercial brass and copper alloys offer long-term corrosion resistance, as well as meet the requirements for potable water materials as identified by ASME and CSA standards. In high-cycle environments, ceramics-based cartridges are preferred due to their predictable wear patterns that are easily maintainable.

More info on common faucet material specifications:

Finish Longevity

Finishes like PVD, chrome plating, satin nickel, and baked coatings have a direct impact on replacement cycles. A high-traffic restroom is continually subjected to disinfectants and hard-water conditions, making the durability of the finish a lifecycle cost driver.

Additional finish material reference:

Water Efficiency and Sustainability Impacts

WaterSense Criteria

WaterSense certified faucets do typically limit flow to 1.5 gpm at 60 psi for residential applications, while many commercial faucets operate at 0.5 gpm without sacrificing hand-washing performance. As identified earlier, reducing water volume directly reduces hot water load, leading to compounding energy savings.

EPA faucet efficiency reference:

CALGreen and Code Compliance

Meeting or exceeding CALGreen requirements eliminates the possibility of having to retrofit in the future due to non-compliance issues. Savings in large facilities can amount to literally thousands of gallons per day, depending on whether 2.2 gpm faucets or 0.5 gpm faucets are being used.

More on CALGreen fixture requirements:

Accessibility Requirements and Inclusive Design

ADA and ICC A117.1 specifications impact the type of faucet hardware that will be used. The lever-style handles or sensor-activated units assist in meeting the operability requirements of:

- Shall not require more than 5 lbf operating force

- Ability to operate with one hand

- No tight grasping and no rotation of the wrist

Reference for ADA faucet considerations:

System Integration in AEC Workflows

Submittals and BIM Coordination

Technical submittals shall include flow data, material specifications, pressure performance, cartridge type, finish, sensor details if applicable, electronic requirements, and maintenance guidelines. BIM families simplify coordination in complex plumbing layouts and reduce RFI volume during construction.

Maintenance, Servicing, and Standardization

In educational, medical, and transportation environments, predictable part availability and standardized components-aerators, solenoids, cartridges-reduce repair labor and limit downtime. Materials that tolerate daily disinfecting agents extend service life significantly.

Material and maintenance overview reference:

Specification Strategy for Architects and Engineers

Define Project Objectives

Water-use limits, energy strategies, accessibility goals, infection-control requirements, and maintenance capacity should be defined early in design.

Reference all relevant standards

Specifications shall explicitly reference ASME/CSA standards, WaterSense performance criteria, ADA/ICC A 117.1 operability requirements, and CALGreen flow restrictions, as applicable.

Assess Water and Energy Savings

Utility modeling can help in evaluating the long-term benefits of higher-efficiency faucets. In many cases, operational savings exceed the difference in first cost within months or a few years.

Plan for Maintainability

Specify components with high cycle ratings, long-lasting finishes, and easily procurable replacement parts. This reduces lifecycle cost while improving system reliability.

Why Initial Price Is Only a Small Fraction of True Cost

A faucet with a low purchase price can still have:

- Excessive water and energy waste

- Frequent replacement of parts

- Failures in ADA inspections

- Corrosion or degradation of finish

- Downtime in high-use restrooms

- Increased labor burden on facility teams

By contrast, a well-specified, compliant, durable faucet can operate for decades, with predictable maintenance and much lower utility consumption. The marginal increase in upfront cost is offset for the most part by reductions in water usage, energy consumption, and replacement frequency.

Conclusion

Lifecycle cost not first cost should be the driver for specifying fixtures in commercial and institutional environments. Code compliance, water efficiency, durability, accessibility, and maintainability will dominate over the long term. Where architects and engineers incorporate these issues into the earliest design phases, buildings will enjoy reduced operating costs and less need for costly retrofits, while significantly enhancing the user experience over a facility’s lifecycle.

Lifecycle Cost Summary Table for Bathroom Fixtures

| Category | Key Factors | What the Content Emphasizes |

|---|---|---|

| Initial Procurement | Fixture price, valves, installation labor | First cost is only a small fraction of true lifecycle cost. |

| Utility Consumption | Water usage, hot water demand, wastewater load | Lower flow rates reduce operating cost and energy consumption. |

| Maintenance & Repair | Cartridges, O-rings, solenoids, sensors, finish wear | High-cycle cartridges and durable finishes reduce long-term labor and parts costs. |

| Durability & Materials | Brass/copper alloys, ceramic cartridges, corrosion resistance | Long-term reliability depends heavily on material quality and mechanical strength. |

| Finish Longevity | PVD, chrome plating, baked coatings, hard-water resistance | Finishes affect replacement frequency, especially in high-traffic buildings. |

| Compliance & Regulatory Risk | CALGreen, WaterSense, ASME/CSA, ADA, ICC A117.1 | Non-compliance can trigger costly retrofits; compliant fixtures reduce risk. |

| Water Efficiency | Flow rate, WaterSense certification, commercial 0.5 gpm | Reduced water volume directly lowers energy and lifetime operating costs. |

| Accessibility Requirements | 5 lbf max force, no wrist rotation, one-hand operation | ADA and ICC A117.1 influence hardware choice (lever or sensor-activated). |

| System Integration | BIM data, submittals, coordination, electronic requirements | Proper documentation reduces RFIs and coordination issues during construction. |

| Standardization & Operations | Aerators, solenoids, cartridges, compatibility | Standardized components reduce downtime and simplify maintenance workflows. |

| Operational Continuity | Part availability, durability, Ease of servicing | Predictable maintenance avoids interruptions in high-use restrooms. |

| Long-Term Value | Reduced water/energy waste, fewer replacements, extended lifespan | High-quality fixtures often outperform low-cost options within months or years. |