Why Sensor Technology Choice Matters in AEC Projects

Sensor-operated faucets are now standard in commercial and institutional settings, driven by hygiene expectations, water-use regulations, and accessibility requirements. The underlying sensor technology—Infrared (IR) or Time-of-Flight (ToF)—directly affects:

- Water efficiency and WaterSense and CALGreen compliance

- Accessibility performance under ADA and U.S. Access Board guidelines

- Resistance in extreme environmental conditions

- Reliability across variations in lighting, material, and geometry

- Integration with building management systems, or connected facility platforms

Most commercial faucets today use either traditional infrared reflectivity sensing or newer optical Time-of-Flight distance sensing. Both approaches can meet building codes, but their behavior differs significantly in real-world architectural conditions.

Infrared Sensor Taps

Principle of Operation

Infrared sensors emit near-infrared light and detect changes in reflected intensity when a user’s hands enter the basin area. Activation requires a certain threshold of reflected light, which makes the system sensitive to:

- Material reflectance: shiny metal, matte stone, black surface

- Skin type and glove materials

- Ambient light, daylighting or glare

- Geometrical relations including faucet, basin and counter

Strengths of IR

- Available today in most commercial plumbing markets

- Lower component and unit cost

- Well-known by maintenance teams

- Ideal for controlled-lighting and matte-surface basins.

Limitations of IR

Because IR is dependent on reflectivity, performance differs with finishes and lighting:

- Highly reflective surfaces may cause false triggers.

- Matte black or dark stone basins may be under-reflecting IR, thus creating misfires

- Daylight changes may be demanding sensitivity adjustments.

- Multi-user trough basins provide more cross-activation opportunities.

These factors reflect the commissioning time and long-term stability of operation.

Time-of-Flight (ToF) Sensor Faucets

Operating Principle

Time-of-Flight sensors measure the time for a pulsed or modulated beam of light to return from a target, generating an actual distance measurement instead of relying on reflected brightness.

This allows the detection zone to be defined as a precise distance window, independent of reflectance.

Performance Characteristics

ToF provides:

- Reliable Detection Regardless of Color or Surface Finish

- Glare, downlights or difference in daylight resistance

- Reduced false activations

- predictable shutdown behaviour

These characteristics make ToF highly reliable in complex interiors such as public transit hubs, healthcare facilities, and modern corporate environments with glossy materials.

Resistance and Ingress Protection

Many ToF sensor pods are sealed to IP65 or IP67, offering:

- Protection against cleaning chemicals, spray, and humidity

- Long life in healthcare of food service cleaning regimens

- Reliability for highly utilized public facilities enhanced.

Accessibility and ADA Considerations

Core ADA Requirements

ADA and U.S. Access Board guidance require that faucet controls:

- Be operable with one hand, without grasping, pinching, or twisting

- Shall not require more than 5 lbf of force

- Be within accessible reach ranges

- Approach and allow for proper clearance over knees and toes

Useful references:

IR vs. ToF for Accessibility

Sensor faucets inherently support operable-part requirements. However, ToF provides a more predictable activation zone, which helps people:

- Approaching from seated positions

- With little use of the upper body

- Who are dependent upon stable proximity sensing instead of reflectance-based detection

IR may require hands to be closer to the spout depending on basin geometry and lighting conditions.

Water Efficiency: WaterSense and CALGreen

WaterSense

WaterSense labeled bathroom sink faucets shall meet:

- Maximum 1.5 gpm at 60 psi

- Minimum 0.8 gpm at 20 psi

References:

- WaterSense Bathroom Faucets

- WaterSense at Work (Faucets Section PDF):

WaterSense at Work – Faucets Section

Sensor type is not regulated; performance depends on how consistently the faucet activates and shuts off. ToF usually reduces “run-on” due to more precise detection.

CALGreen

CALGreen lists the maximum flow rates for nonresidential faucets:

- ≤ 0.5 gpm for public lavatory faucets

- ≤ 0.2 gal per cycle for metering faucets

References:

- CALGreen Overview: CALGreen Overview

- CALGreen Resources: CALGreen Resources

- CALGreen Water Requirements Summary: CALGreen Water Requirements Summary

ToF helps maintain perceived responsiveness at lower flow rates by avoiding false activations.

ASME and Mechanical/Electrical Standards

Commercial faucets shall be listed to:

- ASME A112.18.1 / CSA B125.1 – Plumbing supply fittings

References:

- ASME Standard: Plumbing Supply Fittings – ASME

- ANSI Summary: ANSI/ASME A112.18.1-2018 / CSA B125.1-18 Plumbing Fittings

The full assembly—including the electronic valve, sensor pod, and housing—should be certified. Electrical components typically require UL/IEC safety and EMC compliance.

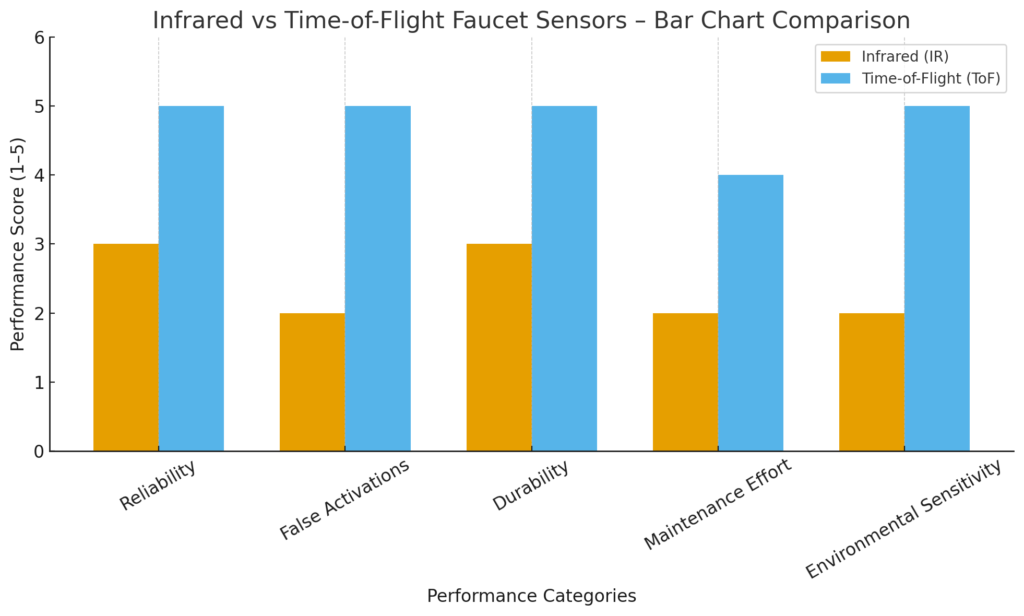

Comparative Engineering Analysis

Detection Behavior

Infra-red:

- Reflectivity-dependent

- Variable performance depending on high-gloss or low-reflectance environment

- Larger detect cone can result in unintentional activation.

Time-of-Flight:

- Measures exact distance

- Compatible with any color or reflectance of surface

- Lower false-trigger rates

Durability

Basically, it is better sealed and more stable against:

- High humidity

- Sanitizing spray-down

- Frequent cleaning cycles

IR modules are designed differently and, therefore, more recalibrations are needed.

Water and Energy Performance

IR faucets can create more ghost activations.

Tof is offering more predictable shut-off behaviour.

Supports more accurate modeling of water efficiency for LEED, CALGreen, or WaterSense projects

Maintenance

IR is sensitive, requiring tuning based on finishes or changes in lighting.

ToF uses fixed thresholds over distance-easier to standardize fleet-wide

ToF provides better telemetry input for restrooms.

System Integration and BMS/IoT

Modern facilities often incorporate plumbing devices into digital ecosystems for:

- Usage tracking

- Battery Level Monitoring

- Predictive maintenance

- Remote configuration

ToF modules provide cleaner, more stable input data for analytics, allowing for better control logic and facility reporting.

Practical Specification Guidelines

When IR Is Appropriate

- Controlled light environments

- Matte or low-sheen materials

- Limited need for telemetry

- Strict initial cost limits

Indicated Use of ToF

- Health care, aviation, education, and transportation

- High-volume public restrooms

- Interiors composed of glass, stone, and other polished metals

- BMS-integrated “intelligent toilet” designs

- Projects targeting WaterSense, CALGreen, or aggressive water performance goals

The details that must be included in the specifications are:

- ToF or equivalent optical distance sensing

- Predefined activation window

- Minimum IP rating: IP65–IP67

- Compliant with ASME A112.18.1/CSA B125.1

- Verification of flow compatibility at system pressure

Recommendation for AEC Teams

Architects

- Coordinate activation zone, basin geometry, and clear floor space

- Document detect zone in elevations as per operable part diagrams

- Prefer ToF where material reflectance is a design feature

Mechanical Engineers

- Evaluate duty cycles for water modeling

- Confirm ASME, WaterSense, and CALGreen documentation

- Select ToF for stable low-flow performance at public lavatories

Owners & Facility Managers

- Consider lifecycle cost, not unit cost

- Standardize across building portfolios

- Use telemetry for predictive maintenance and resource optimization

Conclusion

Time-of-Flight sensing provides superior stability, lower false activation rates, and predictable commissioning outcomes across diverse architectural conditions. Infrared remains viable for simpler, matte-finish, static-lighting installations. Both technologies can be fully code-compliant, but ToF offers a more resilient and future-ready solution—particularly for high-traffic, design-intensive, or performance-driven commercial projects.

| Dimension | Infrared (IR) Faucets | Time-of-Flight (ToF) Faucets |

|---|---|---|

| Sensing principle | Detects reflected IR brightness. | Measures distance via light travel time. |

| Finish & color sensitivity | Performance varies with shiny, dark, or matte surfaces. | Largely independent of color/finish. |

| Lighting sensitivity | Affected by daylight, glare, and lighting changes. | More stable under varied lighting. |

| False activations | Wider detect cone; more ghost activations, especially in troughs. | Tighter zone, fewer false triggers. |

| Durability / sealing | Sealing level varies by product. | Often IP65–IP67, better for harsh cleaning. |

| Accessibility behavior | Activation point can shift with finishes/lighting. | Predictable activation zone, helpful for ADA users. |

| Water performance | More run-on, harder to model savings. | Predictable shut-off, supports CALGreen/WaterSense goals. |

| Best suited for | Controlled light, matte finishes, lowest first cost. | High-traffic, design-intensive, BMS-connected and performance-driven projects. |