Specifying Faucets for Healthcare Environments: Standards, Materials, and Compliance

Health care faucets must balance infection control, accessibility, water efficiency, and durability. This guide outlines specification criteria aligned with ADA, EPA WaterSense, CALGreen, and ASME standards—covering materials, hydraulics, and system integration.

Regulatory and Standards Framework

ADA Requirements for Accessible Lavatory Faucets

Key ADA references for healthcare plumbing fixture compliance:

Key requirements related to faucets include:

- Operable with one hand without tight grasping, pinching, or twisting of the wrist.

- Maximum operating force: 5 lbf (22.2 N).

- Controls within ADA reach ranges.

- Under-sink piping insulated or arranged to avoid contact.

Specification Implications

- Use lever handles, wrist-blade handles, or sensor-operated faucets.

- Coordinate heights and clearances of lavatories with ADA requirements.

- Insulate or enclose supply and drain piping.

Water Efficiency: EPA WaterSense

WaterSense specifies efficiency and performance criteria for lavatory faucets.

Typical WaterSense criteria:

- 1.5 gpm maximum at 60 psi (historical requirement)

- 0.8 gpm minimum at 20 psi

- Draft revisions reduce maximum to 1.2 gpm

Healthcare Implications

- WaterSense faucets common in public/visitor and staff restrooms.

- Clinical handwash stations may require higher flow for rinsing and splash control.

- Specify WaterSense only where clinically appropriate and code-compliant.

CALGreen and Jurisdictional Requirements

CALGreen sets mandatory nonresidential flow-rate limits.

Common CALGreen provisions:

- 0.5 gpm maximum at 60 psi

- Metering faucets: ≤ 0.20 gallons per cycle

Specification Implications

- Where CALGreen applies, its stricter limit prevails over WaterSense.

- Coordinate clinical flow targets with function + code.

ASME A112.18.1/CSA B125.1 — Plumbing Supply Fittings

This standard defines design, performance, and endurance requirements for faucets.

Includes:

- Flow rate tolerances

- Endurance cycle testing

- Corrosion resistance testing

- Pressure/temperature testing

Specification Implications

- All healthcare faucets should be listed to ASME A112.18.1/CSA B125.1.

- WaterSense labeling is layered on top of ASME listing.

Infection-Control Considerations

Sink and Faucet as Pathogen Vectors

Healthcare sinks are recognized reservoirs. Design should reduce splash, aerosolization, and biofilm risk.

Key considerations:

- Use deeper basins with appropriate spout offset to reduce splash.

- Avoid directing flow toward the drain.

- Prefer smooth surfaces with minimal ledges.

Spout Reach, Height, and Offset

- Hand-washing stations require minimum 6" spout reach.

- Offset spout outlet away from the drain.

- Hands-free controls favored in clinical areas.

Video Reference

Practical Design Checklist

For each faucet, verify:

- Intended use zone (public, staff, clinical, scrub)

- ADA compliance: reach, controls, barriers

- Infection-control review of spout and basin geometry

- WaterSense/CALGreen compliance where applicable

- ASME listing and flow compatibility with TMVs

- Sensor/BAS integration needs

- Maintainability and spare-parts standardization

Summary Table

| Dimension | Key Criteria / Targets | Main References |

|---|---|---|

| Accessibility (ADA) | One-hand operation; no tight grasping/pinching/twisting; ≤ 5 lbf operating force; controls within reach; under-sink piping insulated/guarded. | ADA 2010 + Access Board Chapter 6 |

| Water Efficiency | WaterSense: 1.5 gpm max @ 60 psi (draft 1.2), 0.8 gpm min @ 20 psi; CALGreen: 0.5 gpm max @ 60 psi; metering ≤ 0.20 gal/cycle. | WaterSense + CALGreen |

| Listings & Performance | All faucets listed to ASME A112.18.1/CSA B125.1 (flow tolerance, endurance, corrosion, pressure/temperature tests). | ASME A112.18.1 |

| Infection Control | Deep basins, offset spouts, laminar flow in clinical zones; avoid directing flow at drain; smooth cleanable surfaces; hands-free preferred. | CDC + Alberta + FGI |

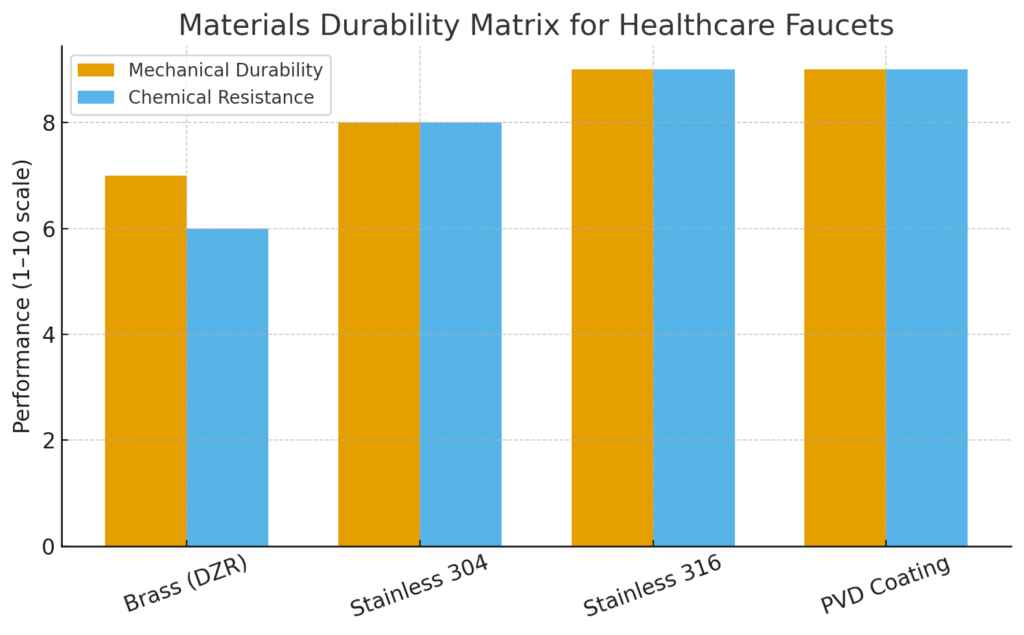

| Materials & Finishes | Low-lead DZR brass or 304/316 stainless; corrosion-resistant internals; PVD finishes; smooth, non-textured surfaces. | ASME tests + manufacturer data |

| Thermal Safety & TMVs | TMVs typically ≤ 110°F (43°C); must work at low flows; supports Legionella water-management strategy. | CDC Water Management |

| Lifecycle & Maintenance | Heavy-duty; 10–15 year parts; top-access cartridges; accessible checks/screens; standardized cartridges. | O&M standards |